Thread Repair For Blind Holes

If you’re looking for an effective solution to repair blind holes, look no further. We can’t help but feel a sense of nostalgia when we think back to the days when fixing damaged threads in stripped holes wasn’t just a job, but a true art form. That it is no longer that way is cause to celebrate! Our product, developed for the mill stands in the steel industry, and proven to be the remedy to platen wear in injection molding machines, is second to none, in any industry; given its hardness and immovability, it is up to the most challenging applications. There´s no need for you to worry any more about stripped holes: the repair done with our product is permanent! It´s a repair that will free you to tend to your bottom line, thus helping to ensure a satisfactory outcome to your mission. If your aim is to secure the mechanical integrity of the line, and fortify your processes´s continuity, safeguarding against downtime, one real possibility is to restore stripped threads in blind holes. There’s nothing to it: you drill out the damaged threads, enlarging the hole, and then use a ratchet or a torque multiplier to turn the insert in…no tapping. A lifetime warranty against mechanical failure is proof of our conviction that, where our product has been installed, there will be no further grief. So contact us today, and let’s get started on restoring your blind holes.

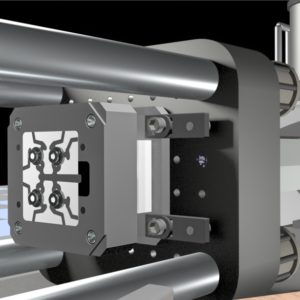

d-Fijo Characteristics

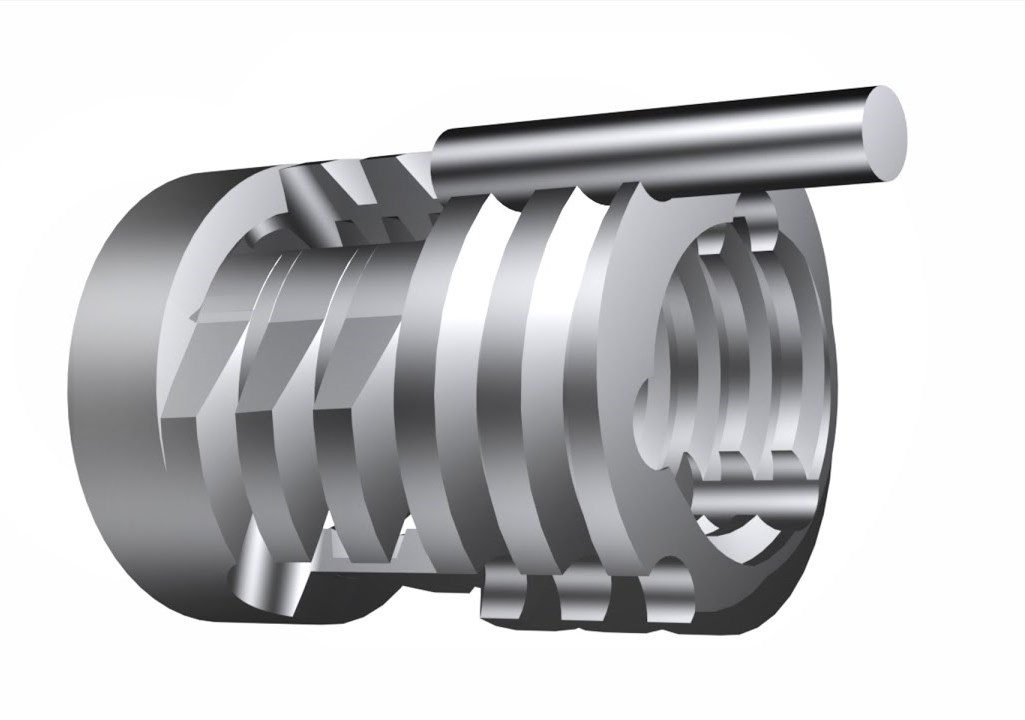

Self-tapping

Self-guiding (Integral Guide)

High Hardness (56 RC)

Ductile (Withstands Torsion)

Register Pin for Extra Security

Left-handed External Thread

Dies Slots that True up Bolts

d-Fijo inserts are self-tapping; all you have to do to put them in is to enlarge the hole, and use a ratchet or a ratchet and torque multiplier. The d-Fijo insert goes in straight thanks to an integral guide; its leading portion is the same size, practically, as the pilot hole. In order to cut its way into place, as it is self-tapping, d-Fijo inserts have an extraordinarily high hardness, like any cutting tool. Although these inserts are hard, they are not brittle; we make d-Fijo inserts out of S7 tool steel, a material that retains the greatest ductility after heat treat. That is necessary because d-Fijo inserts have to hold up to lots of torsion and lateral stress since they work as a tap. d-Fijo inserts have a register pin that keeps them secure even when an impact wrench is used to drive in a damaged bolt…the severest circumstance. They also have a left-handed external thread; in the event a fastener galls with the insert, because of corrosion, when it is removed, d-Fijo inserts will tighten. Last but not least, the treble broach slot pattern that is where the installer seats serves as die slots; the die slots in a d-Fijo insert will true up damaged bolts, thus preventing further thread damage in the line.

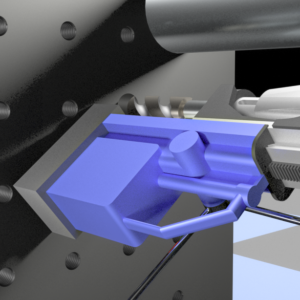

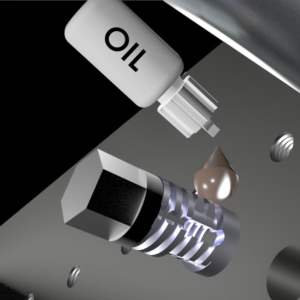

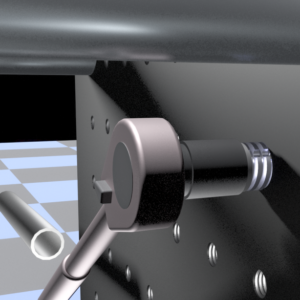

Doing the Repair…

(The following video is of the repair of an injection molding machine. It begins with a catastrophic failure that is all too common in the industry, and subsequently walks you through the repair, a task, in this case, belonging to reactive maintenance as it had escaped the predictive kind)

https://www.youtube.com/watch?v=o7JY8hRGpJ0

Warranty

Cardinal Auxiliaries warrants that repairs made with d-Fijo products will last for the lifetime of your equipment by warranting its product, the only conditions being that the customer has followed the instructions in the manual, and the pilot hole has been bored out to the correct size, magnetic drills with and drill bits being the recommended means (we also recommend annular cutters). This warranty provides for full product replacement and freight, at no charge to the user, in the following circumstances:

Mechanical Failure

(due to stripping, deformation, general wear, and all mechanical causes excluding only corrosion; pullout, breakage, and backout including from vibration)

Bad Workmanship

(in the event the product or accessories inadequately match the design, aren’t machined to tolerance, or have received the wrong hardness during heat treat)

Popular Posts: